MHLS

MHLS

-

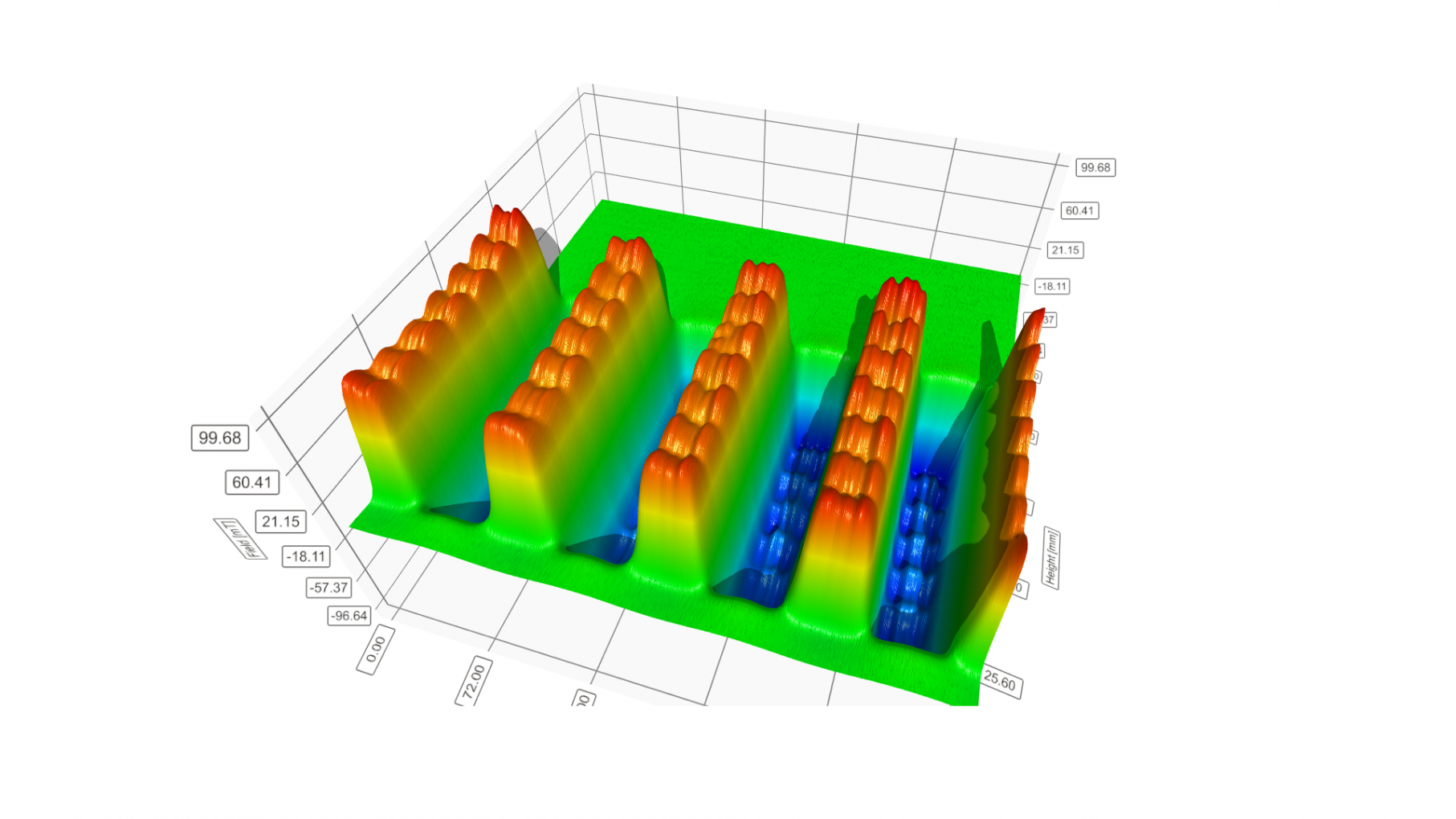

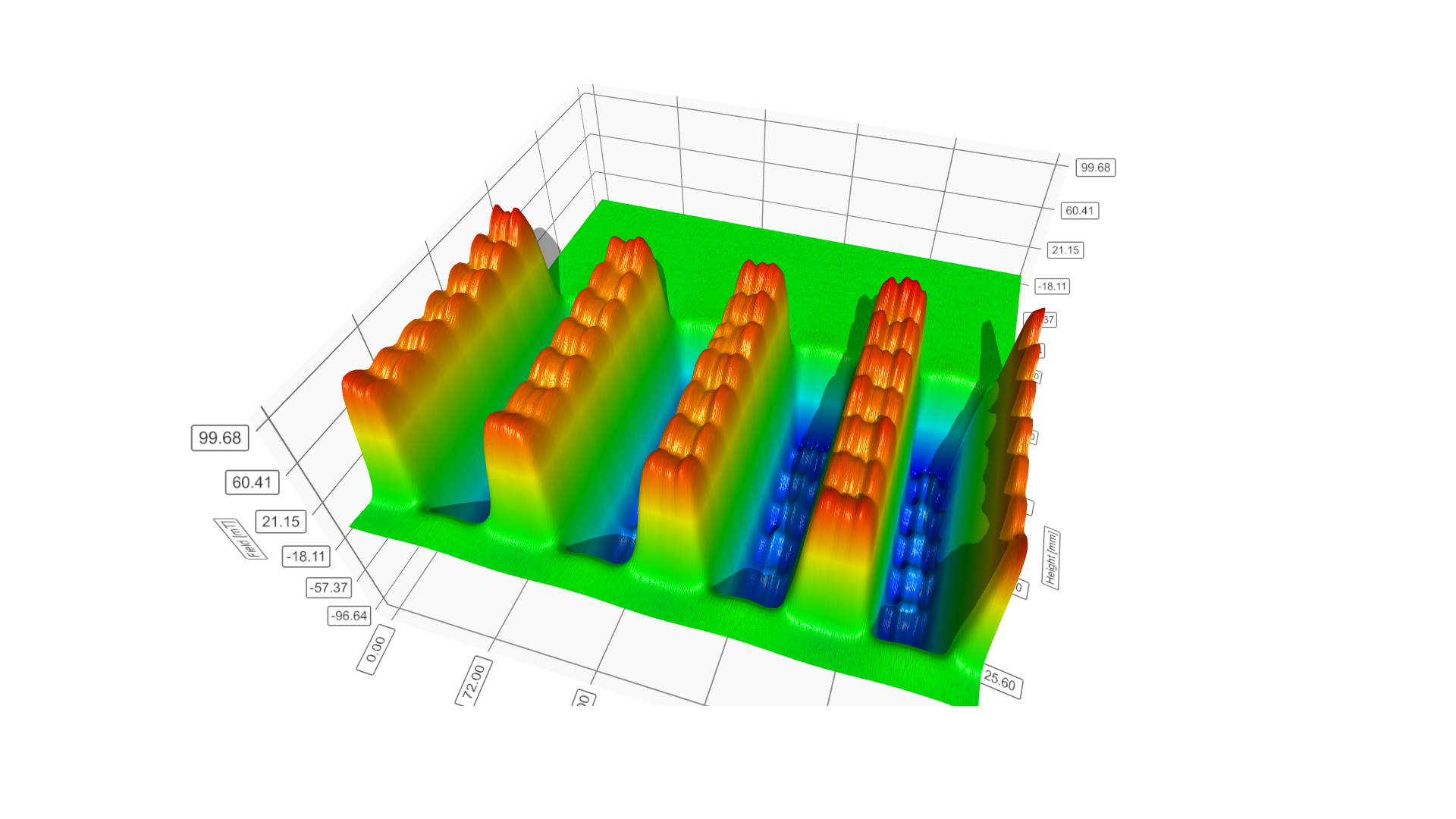

Highly precise and large-area magnet characterization

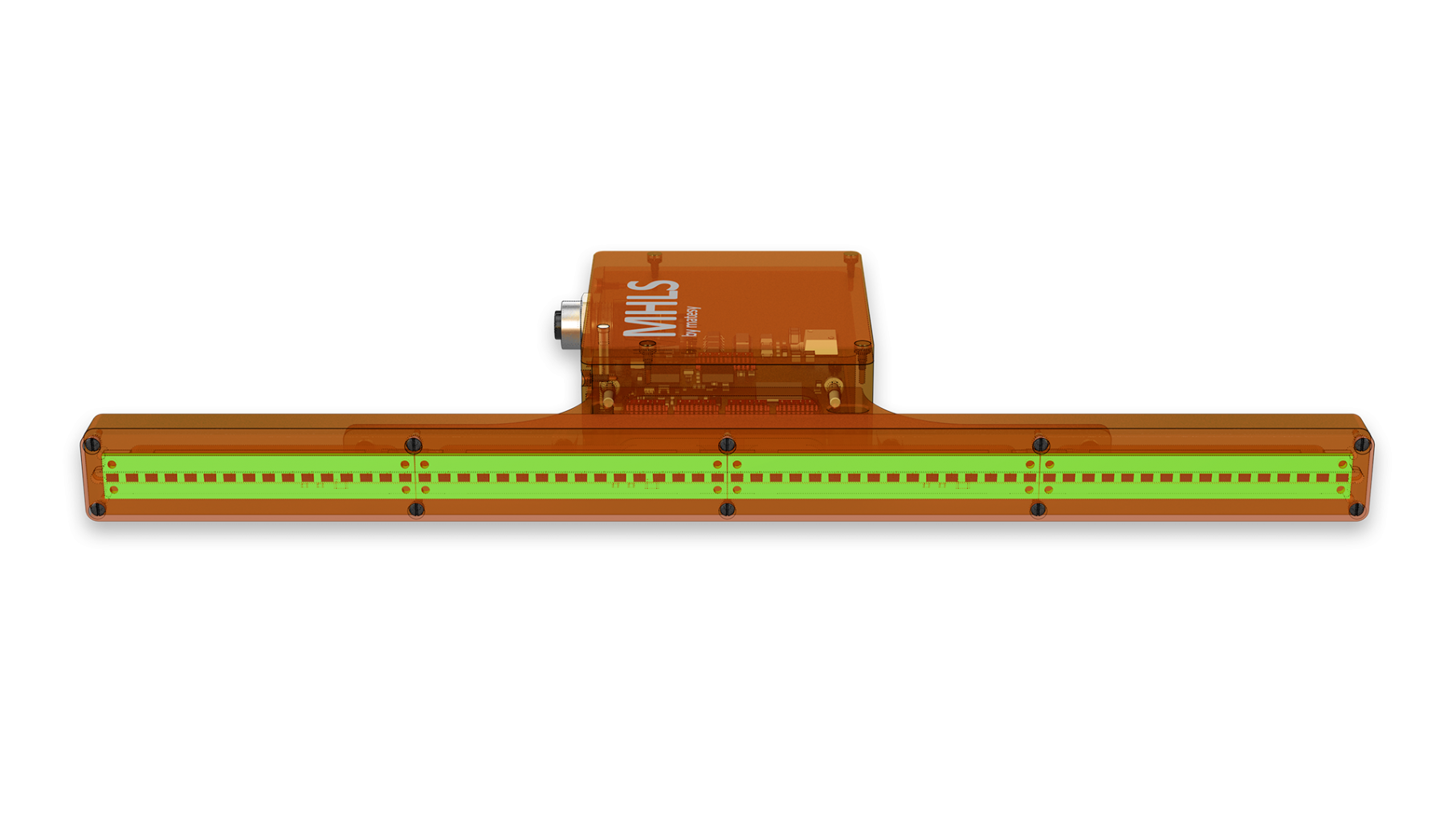

The Matesy Hall Line Sensor, MHLS for short, is the latest pioneering innovation from Matesy GmbH Jena. The newly developed sensor is used for the high-precision, fast and large-area characterization of magnetic elements as well as entire assemblies.

Detail Specification

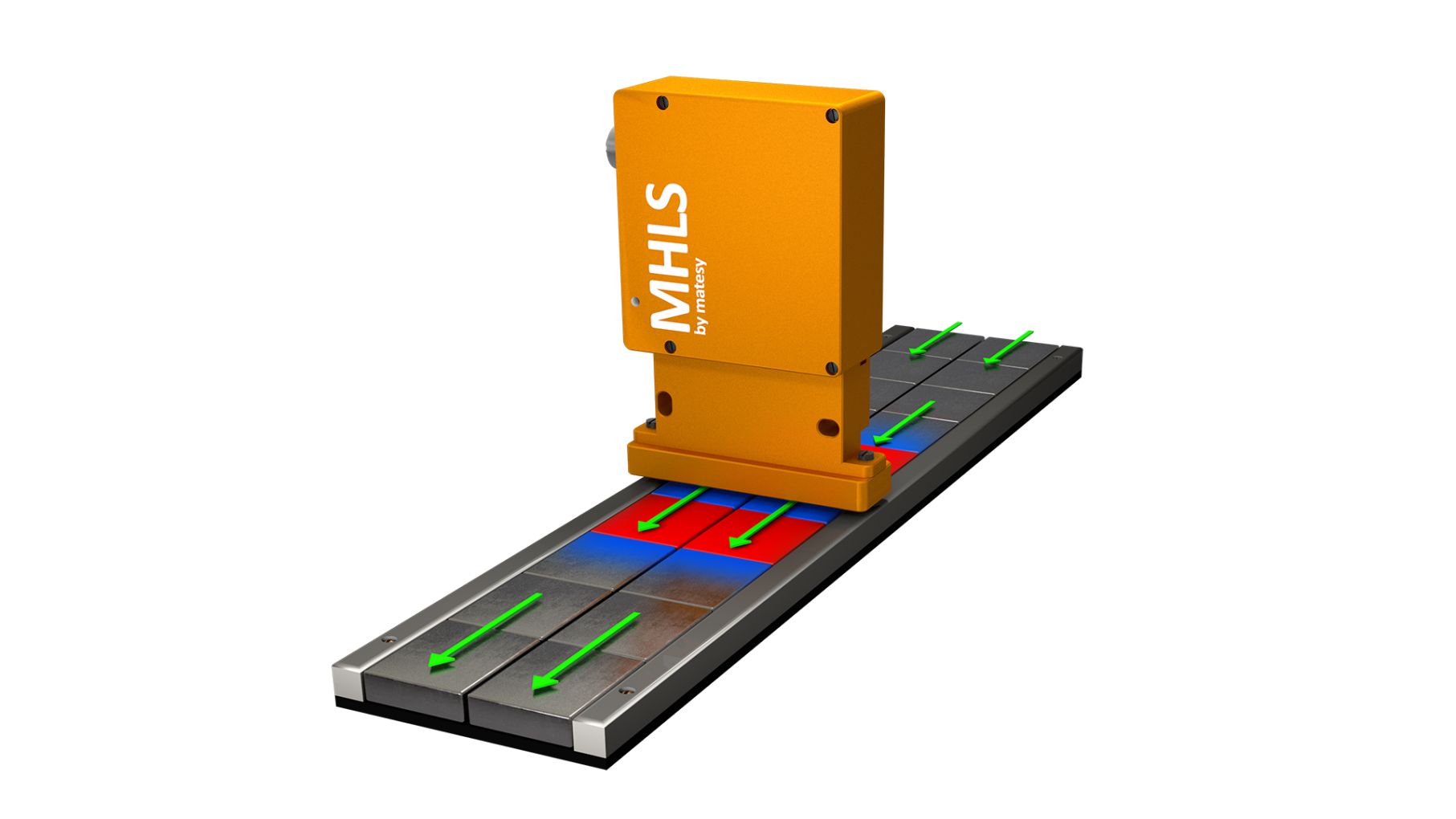

Thanks to its compact and robust design, MHLS can be used extremely flexibly. Especially in the course of the energy and mobility transition, the development of ever more efficient electric motors, in areas such as automobile construction or wind energy, plays an ever-increasing role, where maximum accuracy and quality of the magnetic components used are important. This is exactly where the MHLS sensor comes in and shows its strengths through flexibility, speed and precision. Across all branches of industry, inline testing and development systems for quality control can now be equipped with the MHLS to ensure the best possible real-time control of magnetic components during the production process.

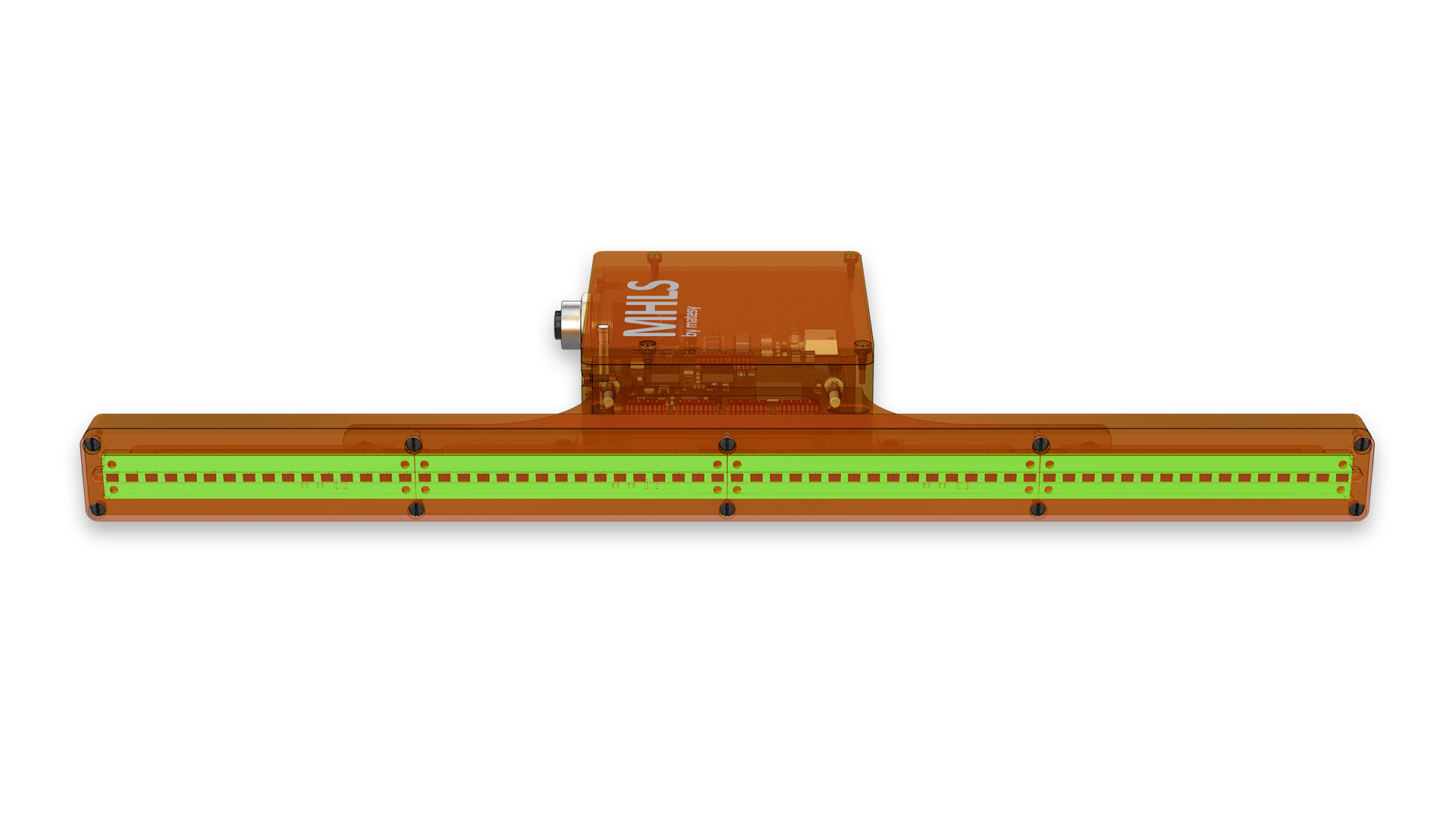

Thanks to data transmission via an industrial bus, integration into existing systems is very easy. The MHLS is available in 4 sizes in stages 80, 160, 240, 320 and with a standard measuring range of ± 800mT. If required, the sensors can be configured for measuring ranges from ± 100mT up to ± 2T and thus cover almost all conceivable applications.

Construction and functionality

The central part of the product is an arrangement of highly integrated 3-axis Hall sensors realized for the first time with this precision and complexity. All sensor triples have an extremely small sensor volume and thus allow pinpoint field and vector determination of the magnetic stray fields. The sensor triples are linearly arranged with high precision at a distance of 2.5 mm on specially developed circuit boards, and interconnected in such a way that a high level of accuracy and a high measuring frequency (sampling rate) are achieved.

Arrangement of the sensors:

16 to 64 high-precision Hall sensor ICs are located 0.6mm below the housing cover at a distance of 2.5mm. Each sensor has its own temperature sensor and is temperature-compensated in addition to the magnetic field calibration.

Benefits

- Reduction of the movable and controlled axes

- Reduction of the software requirements

- Automation through industrial bus system

- High measuring speed 100% control possible with a short cycle time